Contact Info

Email: sales@sealingelement.cn

Mobile: +86-18631992251

Address: Dongliu Village, Tiankou Town, Ren County, Xingtai City, Hebei Province

Product Search

Quickly Find The Product You Need

O-Ring

- Commodity name: O-Ring

- Commodity ID: 0113

- Product Description

-

The rubber sealing ring is an annular cover composed of one or several parts, which is fixed on a ring or washer of the bearing and contacts with another ring or washer or forms a narrow labyrinth gap to prevent the leakage of lubricating oil and the intrusion of foreign objects.

1. Fluorine rubber: it has high temperature resistance, can be used in the environment of -30°C-+250°C, and is resistant to strong oxidants, oils, acids and alkalis. Usually used in high temperature, high vacuum and high pressure environment, suitable for oil environment. Due to various excellent properties, fluorine rubber is widely used in petroleum, chemical industry, aviation, aerospace and other departments.

2. Silicone rubber: It has outstanding high and low temperature resistance performance, maintains good elasticity in the temperature range of -70°C-+260°C, and has the advantages of ozone resistance and weather aging resistance. It is suitable as a sealing lining in thermal machinery pad. Because it has no toxicity, it can be used to make heat insulation, insulation products and medical rubber products.

3. Nitrile rubber: It has excellent oil resistance and aromatic solvent performance, but it is not resistant to ketones, esters, and chlorinated hydrocarbons. Therefore, oil-resistant sealing products mainly use nitrile rubber.

4. Neoprene: It has good oil resistance, solvent resistance, chemical medium and other properties, but it is not resistant to aromatic oils. It is characterized by excellent resistance to weather aging and ozone aging. In production, neoprene rubber is usually used to make door and window sealing strips and diaphragms and general vacuum sealing products;

5. EPDM: It has good temperature resistance, weather resistance and ozone aging performance, and is usually used most widely in door and window sealing strips and the automobile industry.

6. PTFE composite gasket is a new type of sealing material made of PTFE and high-quality synthetic rubber, which is compounded by special production technology. It combines the excellent characteristics of PTFE and rubber. The product not only has excellent corrosion resistance, but also high temperature resistance, non-toxic, anti-adhesive, and has good elasticity and sealing.

Quality Makes The Brand, Integrity Makes The Future

Focusing on oil seals for many years, focusing on "quality", quality first, surviving on the quality of oil seals, seeking development on the quality of oil seals, seeking benefits from product quality, making excellent quality, being an honest oil seal manufacturer, widely used in machinery, Automotive, aerospace, chemical and other fields. At the same time, our company is also committed to continuous innovation, providing customers with customized services to meet the needs of different fields. Our company takes "quality first, customer first" as its corporate purpose, and constantly pursues Excellent quality and service, to provide customers with better solutions

Product advantage

Product Development

|

|

|

|

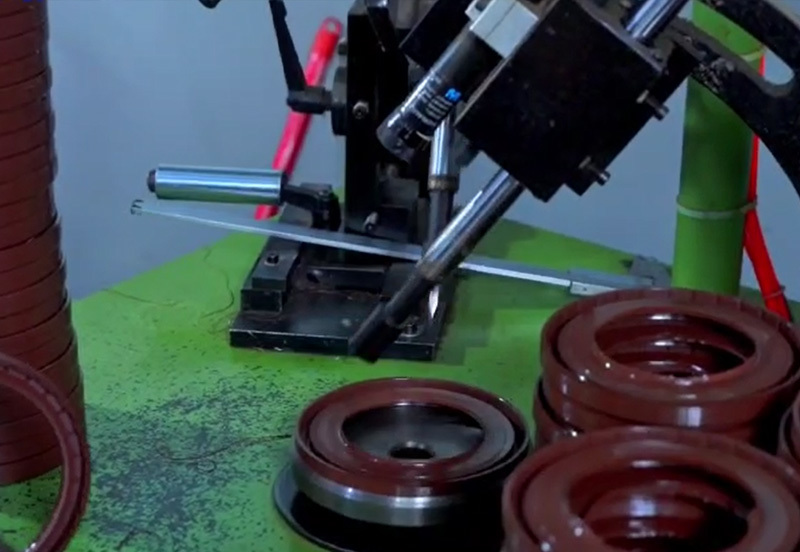

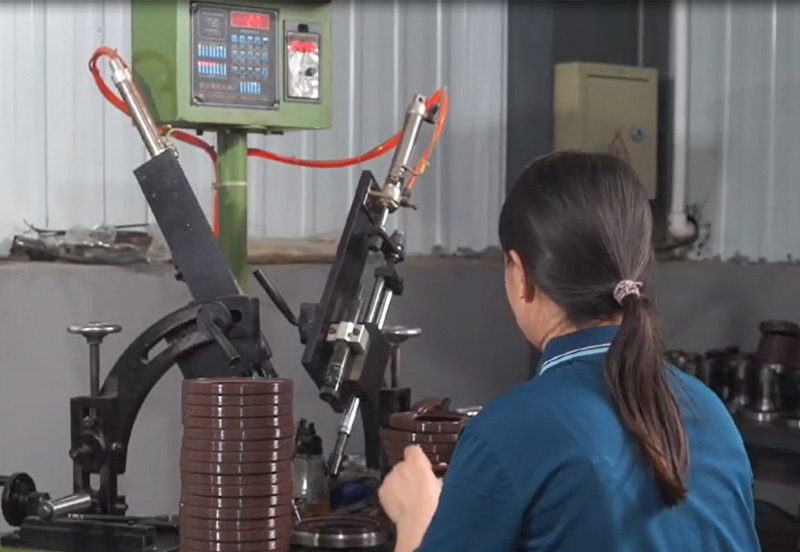

Production workshop

Key words:

Get A Quote

Related Products